Why Are RAMS So Essential for Lab Equipment Movers?

Whether you’re moving sensitive instruments like electron microscopes and spectrometers or high-powered lasers and centrifuges, relocating lab...

We're actively recruiting for a range of roles across sales, engineering, IT and warehouse. Check our careers page to see open positions including apprenticeships.

Whether you’re moving a single piece of equipment or an entire production line, our trusted team of engineers can support every step of your move, from rigging to end-to-end relocation support across the globe.

5 min read

Admin Jun 3, 2024 10:13:50 AM

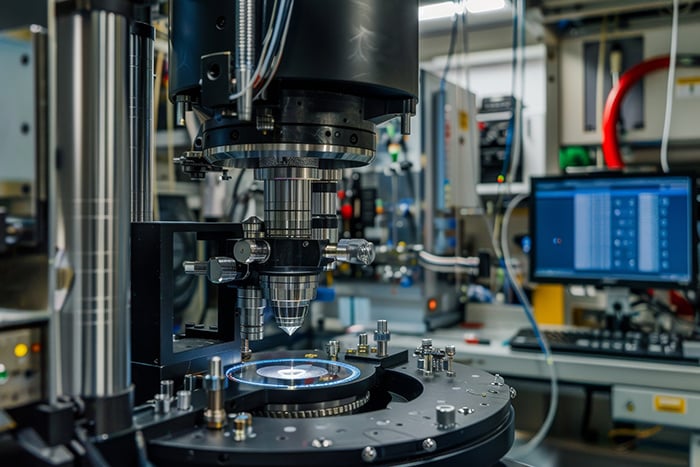

Moving complex pharma equipment and systems into your lab is not your everyday project.

In fact, there are a plethora of factors you need to consider as part of the move. Otherwise, you risk damaging extremely sensitive and high-value equipment and precision components.

Our decades of experience working with complex pharma equipment in labs and cleanrooms across the globe has given us deep insight into the key considerations to factor in to ensure a smooth and efficient move.

Here are the seven things to consider as part of your project.

The old saying, “If you fail to plan then you plan to fail” rings especially true for complex pharma equipment moves.

Equipment assessment and planning is where you identify your equipment’s unique requirements and optimise every step of the process to ensure a successful move.

For example, scanners, capsule-filling machines, and tablet coating machines are highly sensitive to environmental conditions and vibration. So you need to plan how you’ll protect equipment and precision components against these factors. Otherwise, you risk equipment damage, delays and more.

Equipment assessment and planning involves:

Regulatory compliance is more than a bureaucratic checkpoint. It’s integral to protecting your people and equipment throughout the course of the project and working as efficiently as possible.

However, laboratories operating in regulated industries, or those accredited for specific standards, often face additional layers of complexity. So it’s important to understand all regulations that apply to your lab and equipment so you can meet them effectively.

Here are a few key things to consider:

Pharma equipment moves that go wrong can cost significant amounts in repairs or replacements, cause weeks (or even months) of delays or impact production.

For example, labelling equipment and sealers are susceptible to misalignment and sensitive to static, which can impact operational precision and, therefore, production. Risk assessment and mitigation strategies, like custom crating with antistatic materials and shock absorption features, help significantly reduce the likelihood of that happening.

Here are the key things you need to consider:

Safe packing and transportation can be life or death for highly sensitive pharma equipment and precision components.

Freeze dryers and tunnels, for example, need to be kept in strictly controlled temperature environments during transportation to prevent compromise in functionality.

Here are the key things to consider:

Many pieces of lab equipment, such as form fillers and filling lines, require precise calibration to function accurately post-installation.

But, being highly sensitive pieces of equipment, it can be easy to compromise calibration during movement and installation.

So, you’ll need to ensure the equipment functions to its full capacity post-installation. This involves:

Many pieces of lab equipment (for example, freeze dryers) need to be kept in specific environmental conditions, such as specified temperatures or levels of humidity. Otherwise, you risk compromising functionality and causing irreversible damage to precision components.

You’ll need to ensure your facility meets the necessary conditions to operate efficiently, safely and in compliance with regulatory standards. Consider:

Finally, ensure all personnel involved, no matter how big or small a part they have to play, have undergone thorough training on how to safely install, operate and maintain the equipment throughout the process.

For example, operators of capsule filling machines and tablet coating machines need training on the proper handling procedures, so they can minimise mechanical stress and maintain operational efficiency.

As part of this, consider:

For more than 30 years, we’ve been working with complex life sciences, medical and pharmaceutical equipment in laboratories and cleanrooms worldwide.

Stay up to date with the latest news and resources from our experts.

Whether you’re moving sensitive instruments like electron microscopes and spectrometers or high-powered lasers and centrifuges, relocating lab...

The pharmaceutical sector is continuously evolving. And as facilities scale up production, reconfigure cleanrooms, or introduce new technologies, the...

When transporting delicate, high-technology and high-value capital equipment, the right wooden crate can make the difference between carrying out a...