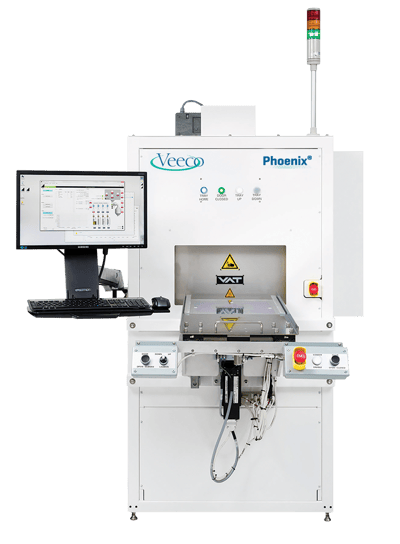

Phoenix

The Phoenix® system is engineered for high throughput and maximum uptime in any fabrication environment, from pilot production to industrial-grade manufacturing. Technologists and researchers rely on the Phoenix® for repeatable, highly accurate film deposition on flat and 3D substrates alike. And with support for up to six individual precursor lines, the Phoenix® delivers solid, liquid, or gaseous process chemistries depending on your thin film needs. A compact footprint and innovative design makes the Phoenix® the practical choice for those with batch production ALD requirements.

Key features include:

- Precise software control of process parameters, including temperature, flow and pressure, for defect-free coatings on even the most sensitive substrates

- Patented ALD Shield™ vapor trap to prevent build-up of deposits and minimizes excess process gases from being exhausted into the environment

- Large process chamber accepts GEN 2.5 substrates, multiple wafer cassettes and larger 3D objects

- Low cost of ownership with minimal startup and operational costs

- Compact footprint that conserves valuable clean room space

- Standard recipes and ALD materials readily available

- Comprehensive support and services worldwide from technical team and PhD scientists

- CE, FCC, and CSA compliant with many built-in safety features

Technical specifications

| Substrate Size | Up to 370 mm x 470 mm (Gen 2.5 Panels) Up to 360 wafers – 100 mm (cassette) Up to 160 wafers – 150 mm (cassette) Up to 100 wafers – 200 mm (cassette) Up to 40 wafers – 300 mm (cassette) Custom holders for 3D objects |

| Dimensions (W x L x H) | 900 mm x 1370 mm x 1700 mm |

| Cabinet | Vented cabinet with smoke detection |

| Power | 208 VAC 3 Phase, 8500 W (excluding pump) |

| Control | Windows™ PC |

| Substrate Temperature | Up to 285º C |

| Deposition Uniformity (AI203) | ≤2% |

| Vacuum Pump | Dry pump ≥350 CFM |

| Compatibility | Cleanroom compatible |

| Precursor Delivery System | Standard 4 lines accommodate solid, liquid and gas precursors Lines independently heated up to 200°C |

| Valves | High speed ALD valves |

| Precursor Cylinders | 3.1 l or 600ml cylinders |

| Carrier/Venting Gas | N2 or Ar MFC flow control |

| Chamber Volume (L x W x H) | (50cm, 40cm,24cm) |