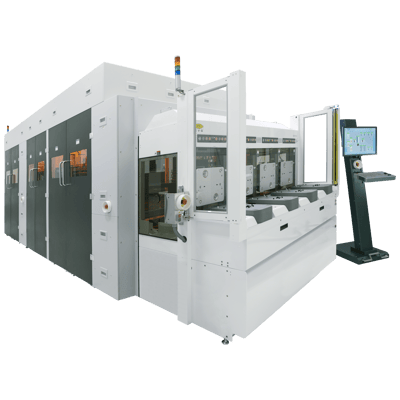

GEMINI

GEMINI is an automated production wafer bonding system which delivers the maximum degree of process integration and automation. For volume manufacturing, this fully automated platform enables wafer-to-wafer alignment and wafer bonding processes up to 200 mm. The system affords device manufacturers the benefits of a high integration level, boosted production output, and a wide range of bonding methods – including silicon fusion, anodic, eutectic bonding and thermo compression – to choose from.

Features

- Fully automated and integrated platform for wafer-to-wafer alignment and wafer bonding

- Configuration options for bottom-side, IR or SmartView alignment

- Multiple bonding chambers

- Wafer handling system is separated from bond chuck handling system

- Modular design with swap-in modules

- Combines all benefits from EVG's precision aligners and EVG®500 series systems

- Minimized footprint compared to stand-alone systems

- Optional process modules:

- LowTemp™ plasma activation

- Wafer cleaning

- Coat module

- UV bond module

- Bake/chill modules

- Alignment verification module