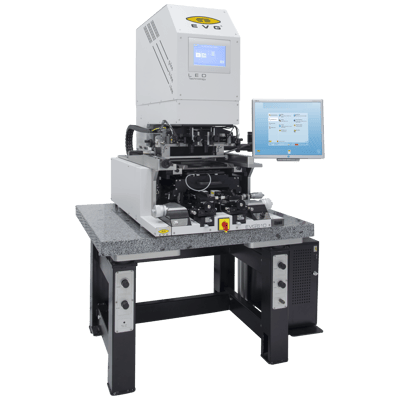

EVG®610

Supporting a range of standard lithography processes – including proximity, soft, hard and vacuum exposure modes – with its back side alignment options, the EVG610 provides additional functions such as nanoimprint lithography (NIL) and bond alignment. The EVG610 provides rapid processing and re-tooling for switching user requirements – the conversion time is under two minutes. In offering a multi user concept which can be adapted from novice to expert level, the EVG610 can be ideal for R&D and university applications.

Features

- Wafer/substrate size from pieces up to 200 mm/8’’

- Top-side and bottom-side alignment capability

- High-precision alignment stage

- Automated wedge compensation sequence

- Motorized and recipe-controlled exposure gap

- Supports the latest UV-LED technology

- Minimized system footprint and facility requirements

- Step-by-step process guidance

- Remote tech support

- Multi-user concept (unlimited number of user accounts and recipes, assignable access rights, different user interface languages)

- Agile processing and conversion re-tooling

- Table top or stand-alone version with anti-vibration granite table

- Additional capabilities:

- Bond alignment

- IR alignment

- Nanoimprint lithography (NIL)