The EMC Directive - officially named Electromagnetic Compatibility (EMC) Directive 2014/30/EU of the European Parliament and of the Council – ensures that electrical and electronic equipment does not generate electromagnetic disturbance, or is not affected by electromagnetic disturbance.

The legislation sets out limits for electromagnetic emissions from equipment, so that mediums such as telecommunication, radio, and other equipment are not disturbed. It also concerns the immunity of equipment to interference, aiming to protect this equipment from disturbance by radio emissions when it is in use.

You can download the full version of the EMC Directive here – it runs to 28 pages. We have created this guide to highlight some of its most important elements.

What does the EMC Directive cover?

The EMC Directive is focused on regulating the compatibility of equipment in relation to electromagnetic fields. Its main objectives are to ensure that:

- Equipment (apparatus and fixed installations) needs to comply with EMC requirements when it is placed on the market and/or taken into service.

- The application of good engineering practice is required for fixed installations, with the possibility that competent authorities of Member States may impose measures in instances of non-compliance.

The EMC Directive covers the majority of finished mains or battery-powered electrical products. Exceptions to the guide include sub assemblies and components without an intrinsic function, (i.e. they are only of use when combined with other components). There are also some exceptions which are already covered in other directives, including; medical devices; communications equipment; road vehicles; agricultural vehicles; and military equipment.

Who enforces the EMC Directive?

In the UK, the EMC Directive is officially implemented by The Electromagnetic Compatibility Regulations 2006. These regulations are enforced by the Trading Standards and Ofcom. The Health and Safety Executive can take part in investigations into non-compliant products, as can the Department of Trade and Industry’s radiocommunication agency, and the British Approvals Board for Telecommunications.

What are the penalties for non compliance?

Businesses which are found to be supplying non-compliant equipment face a maximum penalty of three months' imprisonment, or a £5,000 fine. Typically, manufacturers are asked to replace or recall apparatus which is found to be non-compliant. The sale of apparatus which is found to be non-compliant can be suspended or banned by the relevant authority.

Key EMC Directive responsibilities for manufacturers

Assessments for EMC Directive conformity

There are five classes of assessments which have the purpose of testing for EMC Directive conformity:

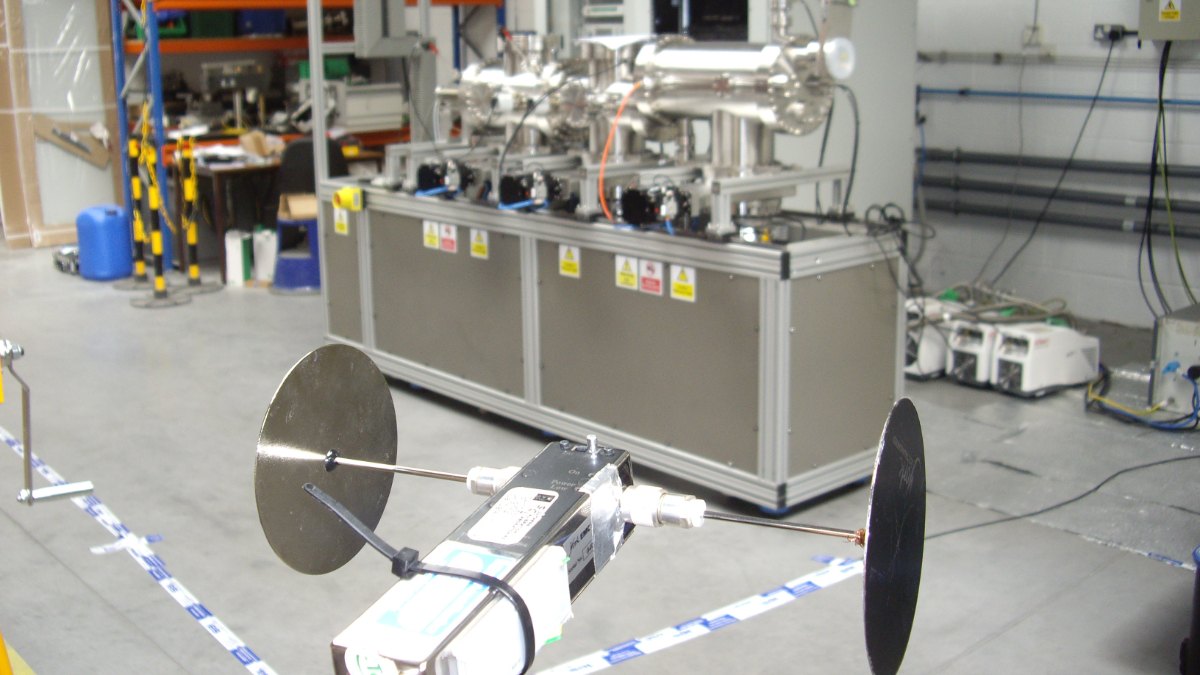

- Radiated emissions - Checks to ensure that the product does not emit unwanted radio signals.

- Conducted emissions - Checks to ensure the product does not send out unwanted signals along its supply connections and connections to any other apparatus.

- Radiated susceptibility - Checks that the product can withstand a typical level of electromagnetic pollution.

- Conducted susceptibility - Checks that the product can withstand a typical level of noise on the power and other connections.

- Electrostatic discharge - Checks that the product is immune to a reasonable amount of static electricity.

Routes to EMC Directive compliance

There are two conventional routes to confirming compliance with the EMC Directive:

1. Standards Route

The electrical products which many manufacturers produce are of no concern in relation to the EMC Directive, and in these cases organisations are able required to take a logical approach to the requirements, which is known as the Standards Route. This way of complying with the EMC Directive allows the manufacturer themselves to compare the performance of their equipment with the harmonised standards set out in the Directive. If they are sure that the standards have been met, manufacturers can make a Declaration of Conformity. In these cases, testing can sometimes be required, but is not mandatory.

2. Technical Construction File

With electrical products for which there are no harmonised standards, or when testing must be conducted outside the confines of the manufacturer’s site in order to demonstrate compliance, the manufacturer is required to put together a Technical Construction File. The results of these assessments, along with the other information in the Technical Construction File, are then audited in order to assure that the electrical products comply with the EMC Directive.

A Technical Construction File typically contains information such as; a general description of the equipment; design and drawings of the equipment; proof (if any) of compliance with harmonised standards; in the absence of standards, a description and proof of how the requirements of the Directive have been met; details on assessments made; a Declaration of Conformity.

CE marking

CE marking provides manufacturers with a way to make a visible declaration that electrical products comply with the EMC Directive. CE marking is a required form of EMC Directive compliance which accompanies a Declaration of Conformity. It also confirms that electrical products have free circulation within the European Economic Area.

You can rely on IES to provide comprehensive CE marking, including all relevant testing, as part of our integrated EMC Directive compliance service.

Electromagnetic fields (EMF) safety

Manufacturers which operate a site which uses high voltage applications need to consider EMF safety. Read about IES’s EMF testing service here.

A trusted partner for EMC Directive conformity

IES offers offer the option of conformity assessments being carried out at your site, or at our own facility, as well as guidance on Technical Construction File compilation and CE marking to declare conformity to the EMC Directive.

Read more on our comprehensive service for EMC Directive compliance, or get in touch to discuss your requirements.